Modelling Services

Modelling is a fundamental service provided by LightCoce that integrates materials’ modelling, process modelling and energy and exergy assessment. Our customers can obtain a complete evaluation of the product, from the material to the environmental impact, and will be able to improve the flexibility and optimization of the manufacturing system. The optimum solutions are obtained for different landscapes and scenarios offering a decision tool to support business plan and marketability.

LIGHTCOCE models lead to design novel materials and components at the scope of lightweight concrete, and conventional and advanced ceramics. Mathematical models consider the different elements present in the manufacturing process in order to develop a holistic model of the whole process. The simulations and models are extended with in-depth evaluations that take into account the resources and emissions of the system.

LIGHTCOCE customers reduce thus the investment in software licensing, simplify the difficulties of using complex numerical tools, eliminate bottlenecks, and reach competitive optimum solutions in a short time.

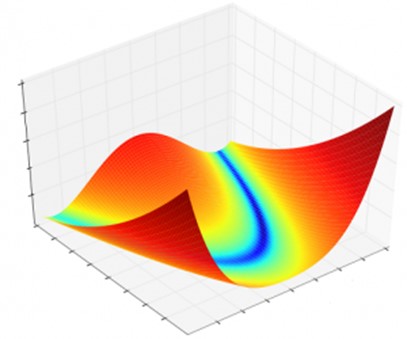

Materials’ modelling is a powerful tool for predicting the properties and behaviour of materials and components minimizing the use of prototyping and testing, and is based on the combination of experimentation, multiscale, multiphysics and data-driven models. Materials’ modelling is a key factor for the development of new and improved materials and the use of existing materials in new applications.

The multiscale modelling strategy links continuum models for component and final products with discrete models as atomistic and mesoscopic giving more insightful and accurate results. This hierarchical strategy simplifies the integration of the process and the materials modelling.

Multiphysics allows the integration of different physical complex behaviours reaching realistic and functionality models. LIGHTCOCE experience in multiphysics includes the following phenomena:

- Mechanics

- Fracture and fatigue

- Damage

- Acoustic

- Impact

- Residual stresses

- Thermodynamics

- Heat, air and moisture transport

- Chemistry

- Diffusion

- Electrical properties and piezolectricity

- Computational fluid dynamics (CFD)

- Wind driven rain

LightCoce provides the integration and optimisation of manufacture (development, upscaling), processes, and multiphysics material modelling solutions through data-driven and machine learning models. This integration is based on innovative Multidisciplinary Design Optimisation (MDO) methods that allow ceramic and concrete materials to be produced in green and sustainable industrial environments.

By taking advantage of advanced computational analysis tools, LightCoce improves simultaneously the design, time and cost of ceramic and concrete materials. The optimisation proposed is driven not only by the performance of the individual manufacture processes but also by their interactions.

This new concept of integration, optimisation and machine learning has already been applied and validated. The analysis of interaction among materials’ properties and the temperature of process and elements has provided excellent results, proving that the methodology used is viable and realistic to optimise ceramic and concrete materials processing.

Currently, process analysis is one of the most relevant disciplines due to the increase in competitiveness and the shortage of raw materials and energy resources. A process analysis can be carried out through different methodologies, including economic, energy, exergy, and thermoeconomic analysis. However, each of these methodologies presents certain difficulties.

The economic analysis considers costs and profits; however, it does not account for the energy that can be wasted or the fraction of the energy that can be transformed into useful work (exergy).

The energy analysis studies the energy efficiency of the process; however, they do not take into account the costs involved to achieve a certain efficiency.

A deeper vision is provided by the exergy analysis, which considers the useful work that enters and leaves each of the subsystems; however, this analysis also does not take into account the costs involved.

The thermo-economic or exergo-economic analysis takes into account both energy, exergy and costs, so it provides better results compared to the other analysis methodologies. This methodology requires the knowledge of more variables than the other types of analysis. The main objective of the thermo-economic analysis´ services are to evaluate and calculate the unit exergy costs (cost per unit of exergy of the processes) in order to try to minimize the unit exergy cost of the products. This methodology is based on a series of steps and rules that allow finding the unknown unit exergy costs.

LightCoce has expertise in conducting thermo-economic and exergo-economic analyses, achieving a deeper view to improve the flexibility and optimisation of the system and of each single unit.